If you are going to replace any one of these on either side. Go ahead and do all of them if you do not know the last time they were replaced. Just to be safe.

This is for a rear 8.8 axle.

Take calibers off.

Pop diff cover

Drain Fluid.

Take out 5/16 cross shaft bolt.

![Image]()

Pull out cross shaft.

![Image]()

45/zj95maxx/Wheel%20bearing/locker008.jpg[/IMG]

Push axle shafts in to remove C-clips from both sides

![Image]()

Pull shaft out.

![Image]()

To remove the seals and bearings you need a slide hammer with a bearing puller attachment on it. You can rent it from nappa or advanced auto parts and get your money back when done.

![Image]()

![Image]()

Simple put the bearing puller end in the shaft, tilt it to go in, then turn in piece so it makes it flat while its inside and slide the hammer to the end with a lot of force, forcing the bearings and seals out.

![Image]()

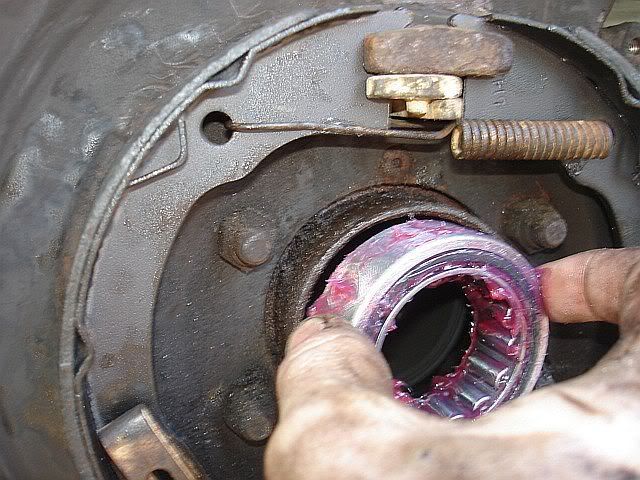

Pack new bearing with grease.

![Image]()

Set it in the opening, and use a screw driver and a hammer to tap it in, make sure to only hit the outter edge. Do not wail on the thing.

![Image]()

![Image]()

Do it until it is fully seated like so.

![Image]()

Now put some gear oil on the seal. and set the seal with the opening facing in towards the bearing, into the shaft.

![Image]()

again, use a screw driver to tap it in. Be carefull not to dent it. Using the screw from the caliber bolt actually works just great.

![Image]()

This is the seal and bearing fully seated

![Image]()

That wasn't hard was it? Now put shafts back in, C-clip. Crossshaft bolt, crossshaft and diff cover back on. Fill it up with fluid, and you are done.

This is for a rear 8.8 axle.

Take calibers off.

Pop diff cover

Drain Fluid.

Take out 5/16 cross shaft bolt.

Pull out cross shaft.

45/zj95maxx/Wheel%20bearing/locker008.jpg[/IMG]

Push axle shafts in to remove C-clips from both sides

Pull shaft out.

To remove the seals and bearings you need a slide hammer with a bearing puller attachment on it. You can rent it from nappa or advanced auto parts and get your money back when done.

Simple put the bearing puller end in the shaft, tilt it to go in, then turn in piece so it makes it flat while its inside and slide the hammer to the end with a lot of force, forcing the bearings and seals out.

Pack new bearing with grease.

Set it in the opening, and use a screw driver and a hammer to tap it in, make sure to only hit the outter edge. Do not wail on the thing.

Do it until it is fully seated like so.

Now put some gear oil on the seal. and set the seal with the opening facing in towards the bearing, into the shaft.

again, use a screw driver to tap it in. Be carefull not to dent it. Using the screw from the caliber bolt actually works just great.

This is the seal and bearing fully seated

That wasn't hard was it? Now put shafts back in, C-clip. Crossshaft bolt, crossshaft and diff cover back on. Fill it up with fluid, and you are done.